- Website -

NEWS INFORMATION

Yuyuan Steel Structure

Prefab Steel Structure Factory vs On-Site Construction: Cost and Efficiency Compared

AUTHOR:yuyuan DATE:2026-02-01 19:20:08 HITS:168

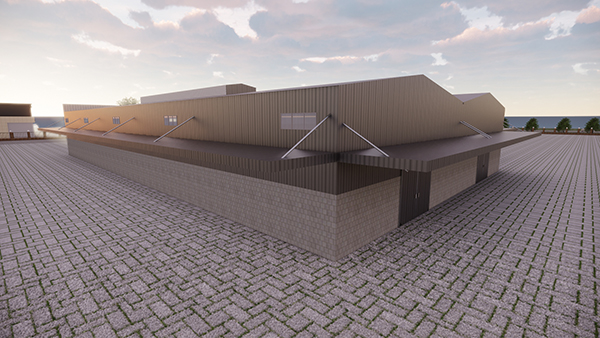

In today’s construction industry, speed, cost control, and quality consistency are more important than ever. One major shift is the growing adoption of solutions produced by a prefab steel structure factory rather than relying solely on traditional on-site construction methods.

A professional prefab steel structure factory manufacturer combines controlled production, automated processing, and bulk supply capability to deliver structural components that arrive ready for installation. Compared with site-built projects, factory-based production improves efficiency, reduces risk, and supports scalable construction.

This article compares prefab steel structure factory production with on-site construction in terms of cost, efficiency, quality, and long-term performance.

|  |

What Is a Prefab Steel Structure Factory?

A prefab steel structure factory produces building components—columns, beams, trusses, frames, and panels—inside a controlled manufacturing environment. Instead of cutting, welding, and assembling everything on the job site, most processes happen in factory production lines.

Key advantages include:

·Standardized manufacturing

·Automated cutting and welding

·Precise quality control

·Bulk production capability

·Faster project delivery

By shifting work into a factory environment, manufacturers improve consistency and scalability for large construction projects.

Traditional On-Site Construction Explained

On-site construction means most fabrication, fitting, and adjustment happens directly at the project location. While flexible, this approach depends heavily on labor conditions, weather, and site management.

Common challenges include:

·Variable workmanship

·Weather delays

·Higher labor costs

·Material waste

·Longer timelines

Without factory production control, cost and efficiency become harder to manage across large projects.

Cost Comparison: Factory Production vs On-Site Labor

Cost is one of the biggest reasons developers choose prefab steel structure factory solutions.

Prefab Steel Structure Factory Costs

Factory-based production reduces cost by:

·Minimizing labor hours

·Reducing material waste

·Improving batch processing

·Using automated equipment

·Supporting bulk supply discounts

Manufacturers optimize cutting layouts and welding sequences in production, lowering unit cost across large volumes.

On-Site Construction Costs

On-site construction often involves:

·Higher labor expenses

·Rework from human error

·Material losses

·Equipment rental costs

·Extended project durations

Without standardized factory production, budgets become harder to predict and control.

Overall, prefab steel structure factory production offers stronger cost stability for medium and large projects.

Efficiency Comparison: Speed and Workflow

Efficiency directly impacts project timelines.

Factory Production Efficiency

In a prefab steel structure factory, workflows are streamlined:

·Parallel processing of components

·Automated fabrication

·Consistent inspection routines

·Rapid batch manufacturing

Production continues regardless of weather, allowing manufacturers to supply large quantities on schedule. Installation becomes assembly-focused rather than fabrication-focused.

On-Site Construction Efficiency

On-site workflows face:

·Weather interruptions

·Sequential task limitations

·Coordination complexity

·Slower assembly speed

Much of the time is spent measuring, cutting, and correcting issues that could be solved in factory production.

Prefab steel structure factory methods significantly shorten overall construction cycles.

Quality and Precision Control

Quality consistency is another major difference.

Factory Quality Control

A professional prefab steel structure factory applies:

·CNC cutting accuracy

·Automated welding

·Dimensional inspection

·Surface treatment control

Standardized testing

Manufacturer-controlled production ensures every beam and column meets design tolerance before shipping.

On-Site Quality Risks

On-site fabrication depends on:

·Manual measurements

·Field welding conditions

·Variable skill levels

·Limited inspection tools

This can lead to misalignment, structural variation, and longer correction cycles compared with factory-built components.

Safety and Environmental Impact

Factory production improves safety and sustainability.

Factory Safety and Sustainability

Prefab steel structure factory systems offer:

·Controlled working environments

·Reduced on-site hazards

·Less dust and noise

·Efficient material usage

·Lower carbon footprint per unit

Bulk production also reduces transport waste and site congestion.

On-Site Safety Challenges

Traditional construction involves:

·High-altitude work

·Welding in open environments

·Heavy manual handling

·Weather exposure

These factors increase risk and reduce productivity compared with factory-based production.

Flexibility and Customization

Many assume factory production limits design freedom, but modern manufacturers offer customization.

Prefab steel structure factory production supports:

·Modular design

·Variable span sizes

·Different load requirements

·Coating and corrosion options

·Adaptable assembly systems

By combining standardized production with flexible engineering, manufacturers balance efficiency and customization.

On-site construction allows changes, but modifications often increase time and cost significantly.

Logistics and Bulk Supply Capability

Large projects require consistent supply.

A prefab steel structure factory provides:

·Scalable production capacity

·Batch consistency

·Predictable lead times

·Coordinated logistics

·Bulk supply management

Instead of sourcing materials piece by piece on-site, factory production delivers complete structural packages ready for installation.

This approach improves scheduling reliability and project planning.

Applications of Prefab Steel Structure Factory Solutions

Prefab steel structures are widely used in:

·Industrial workshops

·Warehouses

·Logistics centers

·Commercial buildings

·Power and energy facilities

Each application benefits from manufacturer-controlled production and factory bulk supply efficiency.

Long-Term Performance and Maintenance

Factory-built structures benefit from consistent surface treatment and connection accuracy.

Advantages include:

·Improved corrosion resistance

·Better load distribution

·Reduced maintenance cycles

·Longer service life

On-site fabricated structures may experience uneven coatings or alignment issues that affect long-term performance.

Conclusion: Why Prefab Steel Structure Factory Production Wins

In summary, choosing a prefab steel structure factory over traditional on-site construction offers clear advantages in cost, efficiency, quality, and safety. Factory production reduces labor dependence, improves precision, shortens timelines, and supports large-scale bulk supply.

With advanced manufacturer-controlled production systems and professional factory manufacturing capability, prefab steel structures deliver predictable results for modern construction projects.

For developers seeking faster delivery, stable budgets, and high structural quality, working with a prefab steel structure factory is no longer an option—it is a strategic advantage for competitive construction in today’s market.

References

GB/T 7714:Gibb A G F. Off-site fabrication: prefabrication, pre-assembly and modularisation[M]. John Wiley & Sons, 1999.

MLA:Gibb, Alistair GF. Off-site fabrication: prefabrication, pre-assembly and modularisation. John Wiley & Sons, 1999.

APA:Gibb, A. G. (1999). Off-site fabrication: prefabrication, pre-assembly and modularisation. John Wiley & Sons.

Hebei Yuyuan Steel Structure Co., Ltd.

Copyright © 2024-2025 https://www.yysteelwarehouse.com. All Rights Reserved Hebei Yuyuan Steel Structure Co., Ltd. All Rights Reserved.

Current Location:

Current Location: