- Website -

NEWS INFORMATION

Yuyuan Steel Structure

Steel Structure Workshops: Strength, Durability, and Manufacturer-Backed Solutions for Business

AUTHOR:yuyuan DATE:2026-01-20 17:24:57 HITS:194

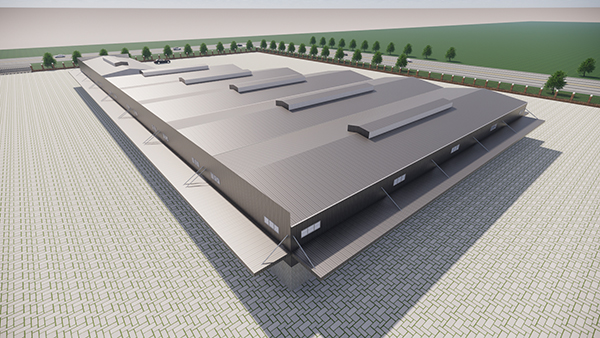

Modern industries demand buildings that are strong, adaptable, and cost-efficient. Steel Structure Workshops have become a preferred solution for manufacturing plants, logistics centers, and commercial facilities because they combine structural reliability with fast construction and scalable production.

A professional Manufacturer with factory-level Production capability plays a key role in delivering these workshops. By integrating engineering design with controlled fabrication, Steel Structure Workshops are produced with consistent quality and supplied in bulk for projects of all sizes.

This article explores the value of Steel Structure Workshops, focusing on strength, durability, and the advantages of factory-backed manufacturing solutions for business development.

|  |

What Are Steel Structure Workshops?

Steel Structure Workshops are industrial buildings fabricated mainly from structural steel components such as columns, beams, and frames. Unlike traditional concrete buildings, these workshops are designed for prefabrication and assembly, allowing most components to be produced inside a factory before being transported to the site.

This factory-based model improves dimensional accuracy and reduces on-site workload. It also allows businesses to customize layout, span, and height while maintaining standardized production efficiency.

A proper understanding of Steel Structure Workshops begins with recognizing their role as both engineered systems and scalable manufacturing products.

Strength: Built for Heavy-Duty Performance

The primary advantage of Steel Structure Workshops is structural strength.

High Load-Bearing Capacity

Steel has excellent tensile and compressive properties, enabling workshops to support heavy equipment, cranes, and storage systems. This makes them suitable for manufacturing, warehousing, and processing operations.

Stable Structural Design

Engineering calculations ensure that frames resist wind loads, seismic forces, and operational stresses. Factory fabrication ensures these designs are executed precisely, reducing construction risks.

As a Production-oriented Manufacturer, maintaining structural accuracy during fabrication is essential to long-term performance.

Durability: Designed for Long-Term Use

Durability is another key factor driving demand for Steel Structure Workshops.

Corrosion Protection

Surface treatments such as blasting and coating protect steel components from moisture, chemicals, and environmental exposure. Proper protection significantly extends service life.

Reduced Deformation

Factory welding and assembly control distortion and ensure consistent geometry. This minimizes maintenance needs and improves operational reliability over time.

Through controlled Factory manufacturing, durability is built into each structural element before delivery.

Factory Production: Efficiency and Consistency

The performance of Steel Structure Workshops depends largely on how they are produced.

Standardized Manufacturing

In a factory environment, cutting, welding, and assembly follow standardized procedures. This reduces variability and improves repeatability across multiple projects.

Quality Control Systems

Dimensional checks, weld inspection, and surface evaluations ensure every component meets production standards before shipment.

This Manufacturer-backed Production system ensures businesses receive consistent quality with predictable timelines.

Flexibility for Business Expansion

Steel Structure Workshops offer adaptability that supports business growth.

Modular Layout Options

Workshops can be designed with large spans, high ceilings, and flexible partitions. This supports machinery installation, workflow optimization, and future expansion.

Fast Installation

Since most work is completed in the factory, on-site assembly time is greatly reduced. Businesses can begin operations sooner, improving return on investment.

Factory-produced Steel Structure Workshops help companies respond quickly to market demands.

Cost Control and Production Scalability

Cost efficiency is critical for industrial construction.

Reduced Labor and Waste

Factory production minimizes material waste and reduces on-site labor requirements. Controlled manufacturing improves resource utilization.

Bulk Supply Capability

A professional Manufacturer can support batch Production and phased delivery schedules. This is especially important for large business parks and multi-facility projects.

Scalable Factory output ensures that Steel Structure Workshops can be supplied reliably as demand grows.

Applications Across Industries

Steel Structure Workshops are widely used in:

·Manufacturing plants

·Warehouses and logistics hubs

·Processing facilities

·Equipment assembly lines

·Commercial and industrial complexes

Their versatility allows them to serve both heavy industry and light manufacturing environments while maintaining structural performance.

Why Manufacturer-Backed Solutions Matter

Choosing Steel Structure Workshops from a Manufacturer with real Factory Production capability provides more than materials. It delivers engineering consistency, quality assurance, and stable supply.

Manufacturer-backed solutions ensure that design, fabrication, inspection, and logistics are integrated into one production system. This reduces risk and improves coordination between planning and construction.

For businesses seeking reliable infrastructure, Steel Structure Workshops produced in a controlled factory environment offer long-term operational value.

Future Trends in Steel Structure Workshops

With the development of smart manufacturing and green construction, Steel Structure Workshops are evolving toward:

·Higher precision fabrication

·Improved energy efficiency

·Digital design integration

·Faster modular installation

These trends strengthen the role of factory-produced workshops in modern industrial development.

Conclusion

Steel Structure Workshops provide businesses with strength, durability, and operational flexibility. Through engineered design and controlled fabrication, these workshops support heavy-duty use while remaining adaptable for growth.

Backed by professional Manufacturer capability and Factory-level Production systems, Steel Structure Workshops deliver consistent quality, scalable supply, and efficient construction solutions for modern enterprises.

As industries continue to expand, factory-produced Steel Structure Workshops remain a reliable foundation for long-term business success and sustainable industrial development.

References

GB/T 7714:Lawson R M, Ogden R G, Bergin R. Application of modular construction in high-rise buildings[J]. Journal of architectural engineering, 2012, 18(2): 148-154.

MLA:Lawson, R. Mark, Ray G. Ogden, and Rory Bergin. "Application of modular construction in high-rise buildings." Journal of architectural engineering 18.2 (2012): 148-154.

APA:Lawson, R. M., Ogden, R. G., & Bergin, R. (2012). Application of modular construction in high-rise buildings. Journal of architectural engineering, 18(2), 148-154.

Hebei Yuyuan Steel Structure Co., Ltd.

Copyright © 2024-2025 https://www.yysteelwarehouse.com. All Rights Reserved Hebei Yuyuan Steel Structure Co., Ltd. All Rights Reserved.

Current Location:

Current Location: